Originally Posted on 14 July 14 2017

Updated Jan. 12, 2022

In almost all design exercises, materials selection is an important element. There are hardly any instances where only one material is suitable for the job, so a means is needed to compare candidate materials.

In almost all design exercises, materials selection is an important element. There are hardly any instances where only one material is suitable for the job, so a means is needed to compare candidate materials.

As examples of materials assessments that are needed:

- Automobiles have substituted increasing amounts of lightweight magnesium and aluminum alloys and polymers for steel

- Aircraft are substituting carbon-fiber-reinforced plastic and titanium alloys for aluminum

- Satellites have long been constructed from exotic composite materials

The selection of a material may be partly based on a numerical comparison of properties and partly qualitative. In some cases, the process may involve some “red lines” – eliminating materials that do not meet a minimum threshold on one or more properties; some may even be illegal.

In other cases, there may be formulae that enable materials properties and their costs to be rigorously compared mathematically.

An important concept is ‘cost per unit of function’. In this case, the optimum material might even change with time, as the relative cost of various materials varies. Paradoxically, the optimum material might even be different in different locations because the relative costs of materials may vary owing to factors such as trade tariffs and transportation costs.

That’s difficult enough, but of course, in most cases, materials have to provide not just one property but a combination of properties. So to take this logic forward further, the design engineer has to try to decide which properties are most important and assign some sort of weighting order to the properties required. This is often subjective!

Add to this the fact that the available data isn’t always fully available, and it is perhaps no surprise that design engineers tend to stay with the materials with which they are most familiar. This often leads to very conservative design principles.

In areas where highly specialized design comparisons need to be made, highly specialized testing regimes may be instituted. This would be the case, for example, with aircraft wings, where a comparison between aluminum and advanced composites may be needed. Aluminum and composites fail in different ways, so it is impossible to define material properties that can be compared in a meaningful way. That is why accelerated testing in comparable circumstances (load and environmental) is the only meaningful comparison; however, a first-order assessment can still be made by comparing materials – and perhaps more usefully – materials families or sub-classes.

Against these difficulties, some laudable attempts have been made to provide ways of assisting the materials selection process. In the (broadly) pre-computer days of the 1970s, a comprehensive paper-based materials selection system called the Fulmer Materials Optimizer was published by a UK-based organization called the Fulmer Research Institute – despite its demise in 1990, some dedicated ex-employees continue to celebrate its existence here!

The Optimizer was the mastermind of Norman Waterman, and following his departure, it was later taken on by myself, amongst others. The publication was later re-launched by the Dutch publishing company as the Elsevier Materials Selector.

Many of the ideas progressed in the Optimizer were, in fact, originally based on concepts devised by Cambridge University professor Mike Ashby. He took them forward via a separate organization called Granta Design, where they devised a computerized materials selection – the CES Selector.

The Granta Design company was acquired by Ansys in February 2019. Since that time, the materials selection software has been integrated into the integrated Ansys suite of advanced design services, which include 3D design, additive manufacturing, digital twinning simulation and many others.

The Optimizer contained extensive data about all the materials classes and their relative performance in terms of mechanical, electrical, thermal, corrosion, wear and other specialist properties. Most of the data were presented in simple tabular chart and graphical form, including nomograms – a diagram representing the relations between three or more variable quantities by means of scales, so arranged that the value of one variable could be found by a simple geometrical construction – by drawing a straight line intersecting the other scales at the appropriate values. Fortunately, the advent of computers has meant that the toils of creating and using nomograms have largely disappeared.

Ashby Plots

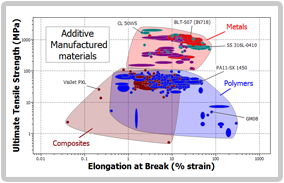

The traditional Ashby plot is a scatter plot that displays two or more properties of many materials or classes of materials. For example, if a key design objective is the stiffness of a plate of the material, then the designer needs material with the optimal combination of density, Young’s modulus, and price.

Regions of the space that materials families (polymers, foams, metals, etc.) can be identified by colored areas. These plots are useful to compare the ratio between different properties.

In the example discussed above, the stiff/light part would have Young’s modulus on one axis and density on the other axis, with one data point on the graph for each candidate material. On such a plot, it is easy to find not only the material with the highest stiffness or that with the lowest density but also that with the best ratio. Using a log scale on both axes facilitates the selection of the material with the best plate stiffness.

Optimizing complex combinations of technical and price properties is a hard process to achieve manually, so rational material selection software is an important tool.

CES Selector

The CES Selector is an expert tool for systematic graphical analysis of materials selection problems. Applying the Ashby methods, users identify candidate materials based on their engineering problem. They can then access more detailed materials datasets to explore those candidates in depth. A key dataset is Prospector Plastics, included in the CES Selector package under license from UL. In 2017, Granta Design announced an extension to its agreement with UL that makes additional Prospector material property and technical information, including the UL Yellow Cards and UL Colorants data. UL Yellow Cards, is a globally recognized safety and quality guarantee that can help demonstrate how your plastics have met a specific set of performance credentials and provide engineers with confidence that their choice of plastic will meet safety requirements.

The UL Prospector Materials Database is available independently online and incorporates its own materials selection capability. Prospector contains around 90,000 plastics datasheets from around 1000 leading materials manufacturing companies and nearly 50,000 UL yellow cards.

The Polymers data series brings together wide-ranging property data for generic polymer grades, data on specific polymer grades from leading plastics data providers, plus information on plastics for additive manufacturing. It includes data on price, environmental impact, temperature-dependent data, creep, stress/strain, and rheological properties.

There are over 400,000 users of the powerful parametric search engine, which allows quick and easy access to property and processing information critical to product development.

Upgrade your materials research tools with Prospector premium services. Available plans include property search, UL Yellow Card properties, OEM specs and more. Learn more.

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

These selectors are great if you’re limiting your interest to mechanical properties, but even then these are massively influenced by how they are processed.

These tools would be better with environmental selection too, e.g. UV, chemical, and humidity and other functional properties such as colourability, cost, sustainability (another whole big topic).