EMI shielding, thermal and electrical conductivity, electro dissipation – these type of specialty coatings are sometimes classified under the general heading of “smart” coatings. However, I define “smart” as coatings that respond “intelligently” to various mechanical, electrical, thermal and optical stimuli, and don’t feel these fit in the category. An excellent article, “Smart Coatings: The Next Big Opportunity in the Coatings Industry”1 can be found in Paint & Coatings Industry magazine.

Electromagnetic Compatibility and Interference

Electromagnetic compatibility (EMC) means an electronics device will perform according to the rated specification in its electromagnetic environment.

Electromagnetic Interference (EMI) occurs when an external source disrupts an electrical circuit by electromagnetic induction, electrostatic coupling, or conduction. Electromagnetic interference can be categorized in two ways:

- Broadband is unintentional radiation from sources such as electric power transmission lines and other high voltage electrical devices, electronic instrumentation and generators

- Narrowband EMI, which transpires from radio and TV stations or cell phones, happens intentionally.

Additional sources include: transmitters, doorbell transformers, toaster ovens, electric blankets, microwaves and touch controlled lamps. Electromagnetic interference at 2.4 GHz can be caused by 802.11b and 802.11g wireless devices, Bluetooth devices, baby monitors, cordless telephones, video senders, and microwave ovens.

EMI Shielding

Since 1979, the U.S. Federal Communications Commission (FCC) has imposed legal limits on electromagnetic emissions from all digital equipment in response to the increased number of digital systems that interfere with radio communications.

In addition, as analytical and other sensitive equipment became more sophisticated and delicate, these devices required protection from external sources of electromagnetivity which would affect the performance.

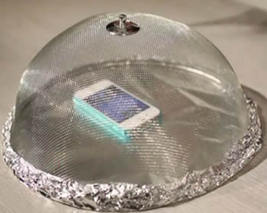

Although there have been methods to dampen the effect of EMI for many years, these included the use of metallic (often copper) Faraday cages (Figure 1), which are actually mesh structures. In the case of analytical labs, these had to be built in to the walls, which has led to the search for more cost-effective and simpler methods.

The discovery of single- and multi-walled nanotubes as well as other conductive, carbonaceous materials, has led to the next generation of EMI-shielding materials. Metals such as copper, silver, nickel and nickel-plated carbon fibers, are also used in coatings, sealants and gaskets to mitigate or eliminate EMI, as well as dissipate Electrostatic Discharge (ESD)3. Other materials are also used, including conductive paints, sealants, and composites.

Beyond Electronics

Besides the obvious applications for electronics, EMI-shielding materials can also be employed to reduce the radar signature of vehicles such as aircraft, ships and ground vehicles. This, along with specific shapes, have enabled the military to effectively and wholly hide structures from radar detection. They can also be used to protect rooms from eavesdropping; which often use enhanced listening devices.

In the metallic coating solution, it has to be filled sufficiently enough such that the particles are in close proximity to one another and touch. This means small particles, or a distribution to minimize volume voids, which then can affect rheology, etc.

With carbonaceous materials, they also have to touch, but are less dense, and in the case of single- or multi-walled nanotubes, can be effective at a relatively low loading in coatings, including paints, sealants and adhesives.

Thermal and Electrical Conductivity

In some ways, electrical and thermal conductivity are similar. The types of technologies to achieve each in coatings can be comparable. Both are presented here, but an article in Coatings Tech, “Being Creative with Electrically Conductive Paint”4 offers a thorough explanation of the latter, should you want a more complete overview.

Over the past several years, electrically conductive inks and paints have been developed to replace wiring in printed circuit board circuitry, which has helped decrease production costs and makes many electronic devices affordable.

Thermal conductivity is important in mitigating heat build-up or removing heat as quickly as possible. One specific example is in air conditioning. Coils are typically copper, while the fins are aluminum. An increase in heat removal from the fins and coils will increase the efficiency of the heat exchange by 5-15 percent, thus reducing operating costs. For large (e.g. 20 ton) units, this translates to hundreds of thousands of dollars annually.

On the other end of the spectrum is non-conductivity (insulation). This is the key to maintaining the temperature in equipment like an oven, refractory, or gas turbine. Many of these are ceramic-based, since they deploy high temperatures, and ceramic or glass microspheres provide an insulating air void.

Electrostatic Dissipation (aka Electrostatic Discharge)

When you walk across a carpet in a dry room and touch a metal object, static creates a spark. If the metal object you touched was a sensitive instrument, you may damage it, or throw off its calibration. For that reason, it is important to dissipate the charge, so it doesn’t create a spark. Lightning is an extreme case of electrostatic dissipation as it hits an object on the ground. Sometimes a discharge is desired, as in corona discharge, which may be used to treat the surface of plastics to improve adhesion of an applied coating.

Sparks around flammable gasses, medical equipment, integrated circuits, etc. are highly undesirable. For that reason, various techniques are utilized such as grounding, or ESD. Measures to eliminate the potential for sparks include grounding human workers, providing antistatic devices, and controlling humidity. Many sites utilize floor mats at the entranceways to areas of high sensitivity, but coatings can also be used to mitigate and eliminate the generation of small electrical discharges.

In summary, these applications areas for coatings are not well-known, but very important to the markets in which they are used.

References:

- “Smart coatings: the next big opportunity in the coatings industry”

- Shielding Screen information

- Conductive Shielding Paint Application

- “Being Creative with Electrically Conductive Paint”

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Leave a Reply or Comment