Introduction

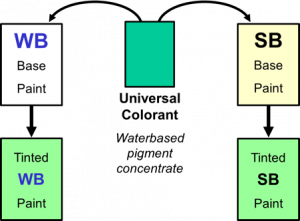

A universal colorant is a concentrated dispersion of colour pigment that is used to tint a base paint. A line of well-designed universal colorants can be used for both water-based paints and solvent-based alkyd paints, most often for architectural applications. Modern universal colorants are solvent-free, water-based materials. The adjustment of colour of the architectural paints can be done either in the production plant (In-Plant tinting) or in the shops where customers buy their paints (Point-of-Sale tinting).

Searching for universal colorant materials?

Prospector® has listings for thousands of products from global suppliers. Review technical data, order samples and more.

The challenges of formulating universal colorants

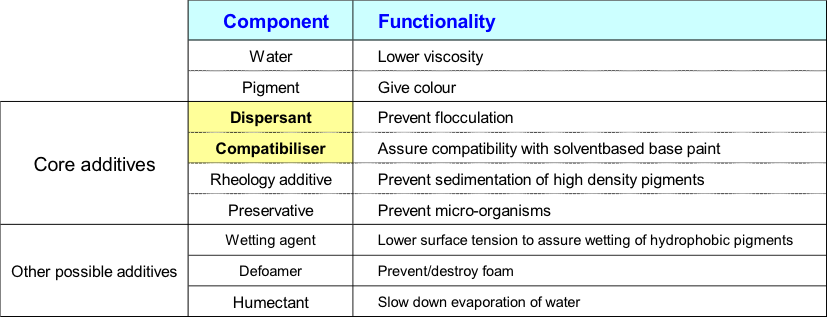

It is already complicated to develop a robust line of water-based colorants that is only used to tint water-based paints. A wide range of different colour pigments must be stabilised by using as few as possible additives. Dispersants are polymeric additives used to provide stability against flocculation. Anchoring, strong adsorption of the dispersant molecules at the surface of the pigment particles, is a key hurdle to take for all types of colorants.

For universal colorants, there are additional problems to overcome.

First, the composition of the water-based colorants must be such that the stabilisation of the pigment particles is assured when the colorants are added to both water-based (WB) and solvent-based (SB) paints.

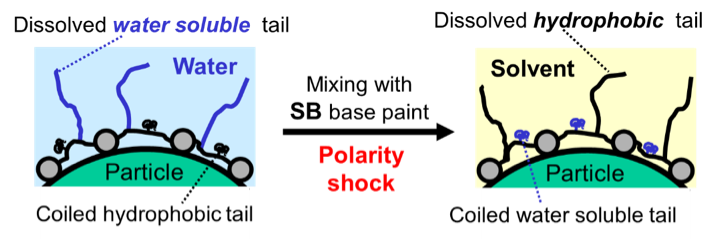

Most often steric stabilisation is used to provide repulsive forces between the solid particles. The dispersant molecules must contain water-soluble tails of sufficient length to assure steric stabilisation in systems that have an aqueous continuous phase, like the colorants themselves and the water-based base paints to which the colorants are added. Also, tails are needed that dissolve in the nonpolar continuous phase of solvent-based architectural alkyd paints, often based on de-aromated white spirit D40 or D60 as solvent.

Secondly, the water of the colorants must be homogeneously distributed in the solvent-based paint when the colorants are mixed with such a base paint. Upon mixing of paint and colorant, the water must be emulsified and stabilised within the solvent-based system.

Additives for universal colorants

Steric stabilisation in both aqueous and nonpolar media can be arranged by using different sorts of soluble tails, that are both part of the dispersant molecules.

In the colorant itself, the pigment particles repel each other because of steric stabilisation provided by water-soluble tails, possibly combined with electrostatic repulsion. This stabilisation mechanism stays intact when the colorant is added to a water-based paint. The hydrophobic tails are not soluble in the aqueous continuous phase. The hydrophobic tails are coiled when the pigment particles and dispersant are surrounded by water. When the universal colorant is added to nonpolar solvent-based base paint, the hydrophobic tails dissolve and stretch. Because of this, the tails provide steric stabilisation in the nonpolar continuous phase consisting of alkyd resin dissolved in organic solvent.

The water-soluble tails are not soluble in the nonpolar continuous phase of the solvent-based paint. Therefore, the water-soluble tails coil when the particles become surrounded by the nonpolar continuous phase of the solvent-based base paint.

It will come as no surprise that it requires skills to develop dispersants that comply with these criteria. Disperbyk®-2060, for inorganic pigments, and Disperbyk®-2061, for organic pigments, are polymeric dispersants designed to make universal colorants for architectural paints.

Preferably, the water of the universal colorants is emulsified to small droplets when the colorants are added to a solvent-based base paint. Several additives, often referred to as compatibilisers, can be used either in the colorants or in the base paints to accomplish this.1

The final products

Despite all the difficulties that must be overcome, high-quality universal colorants are available. Monicolor™ C is a line of solvent-free universal colorants designed to be compatible with both water-based and solvent-based architectural paints.

The future

The development of fool-proof universal colorants has not yet ended. The quality of adsorption of dispersants at the surface of pigment particles must be improved, especially anchoring on the surface of organic pigments. Secondly, not all universal colorants can cope with the shock in polarity when the water-based colorants are added to solvent-based base paints. Finally, the emulsification of water, when colorant is added to solvent-based paints, is often not good enough.

Further reading:

- Settle Down: Factors that Influence Pigment Settling and Stability

- Mix It Up: High Speed Mixers for Paints, Inks & Coatings

- A Home for Architectural Coatings Resources

- Architectural Coatings: Paint Formulations and their Properties

Reference

1. White paper: Past and Future of Universal Colorants in Coatings, Frank Kleinsteinberg (Evonik), October 2017 [PDF]

The views, opinions and technical analyses presented here are those of the author or advertiser, and are not necessarily those of ULProspector.com or UL Solutions. The appearance of this content in the UL Prospector Knowledge Center does not constitute an endorsement by UL Solutions or its affiliates.

All content is subject to copyright and may not be reproduced without prior authorization from UL Solutions or the content author.

The content has been made available for informational and educational purposes only. While the editors of this site may verify the accuracy of its content from time to time, we assume no responsibility for errors made by the author, editorial staff or any other contributor.

UL Solutions does not make any representations or warranties with respect to the accuracy, applicability, fitness or completeness of the content. UL Solutions does not warrant the performance, effectiveness or applicability of sites listed or linked to in any content.

Hello Jochum,

Good to hear from you! With your experience are dispersants used industrially in powder coatings? And are they efficient as there is no water and no solvent? I tried some products from Byk but I have not seen any efficiency for example in light blue powder formulations.

Thank you for your answer.

Yves

I wonder what continuous phase is used in these concentrates. If it is water, where does the water stay in a solvent borne paint? If it is solvent, where does it stay in a water borne paint? The only solution to me would seem a watermiscible solvent like Dowanol PM? Please elaborate.

Dear Yves, Good to hear from you as well. The 2 stabilisation principles used in liquid paints (electrostatic and steric repulsion) are difficult to use in powder coatings (and plastics). It is possible to adsorb interface additives at the surface of the solid particles to prevent direct contact between the surfaces of the particles. This will give lower viscosity and better flow. However, it is difficult to get real particle-particle repulsion in systems that do not contain carrier molecules (like water and solvent). Greetings, Jochum.

Dear Ad, the continuous phase in modern universal colorants is water, without organic solvents. Mixing with water-based base paints is not a problem. The trick used when the water-based colorants are added to solvent-based base paints is that the water from the colorants is emulsified within the solvent-based paint during mixing. Greetings, Jochum.

Contnuous phase in main POS colorants is water or water/ PG. This for reasons of low VOC, optimal -polar-dispersion medium (contribution of electrostatic stabilisation), enabling high pigment loading at good flow, compatibility in main application systems. Water is emulsified in alkyd/ SB systems by compatilisers, additives, as being part of the colorant formulation. Amount of water as added to the SB system through POS colorant addition is low, typically less than 5 pct.

Help me with the actual manufacturing of tinters, how much water and so on

Dear Gerald, as it is not easy to answer this request in a short way, I advise you to contact suppliers of dispersants, like BYK, and ask for starting formulations of colorants.

Hi Gerald,

You can also search Prospector for colorant formulations.

Hope this helps!

Angie

Content Manager, Prospector Knowledge Center

Can you please suggest suitable compatilisers and additive

Dear Pratik:

The innovative additive suppliers have dispersants for universal colorants and compatibilisers in their program. Two examples from Evonik: Tego Dispers 653 is a dispersant that is designed for universal colorants and Tego Color Aid 7060 is a compatibiliser, designed to enable the addition of universal waterbased colorant to solventbased base paint. This compatibilizer must be added to the solventbased base paint. A TDS of both products can be found on the UL Prospector platform.

Thanks for reading,

Jochum

Dear all

We are really much interested in your company’s products and wanted to be a part of your business family and do work with you as a distributor so please pay attention regarding this concern and guide us soon towards it.

Hi Pankaj,

Find the materials you need and global suppliers by joining UL’s Prospector. You’ll find a wealth of information here!” https://www.ulprospector.com

Hi. Thank you for the chemistry lesson I never had… lol

I have a question. I am an artist and mix many of my own colors but I find my universal tints get so thick from standing around and not being able to mix them up properly in their plastic bottles, the medium for them gets used up rapidly leaving a lot of the pigment behind. What can I use to make them a little less thick? I want to transfer them into glass jars so I can mix it properly to make them useful as I don’t want to keep buying new containers of them and have more waste.

I use both water and alkyd based paints depending on the project.

Dear Amelia, thanks for reading my articles.

Basically, thickening of colorants can have 3 causes. The first is evaporation of water and/or solvent (depending on the type of colorant). The remedy is to use cans/bottles that can be completely closed so that evaporation is prevented. Secondly, the plastic might be porous for water/solvent. In either case, thinning the colorants can be done by adding a little water and/or solvent (depending on the type of colorant) and mix well. Of course, you need to know what is in the colorants. You could ask the supplier about that.

The third possible cause is a chemical reaction. Some colorants contain resins and/or vegetable oils that can chemically react with oxygen that is in the air. Mostly, a skin is formed on the material if this so-called oxidative cure occurs. You can reduce this effect by closing the cans immediately (and completely) after use.

Thanks for reading!

Jochum

Hello Jochum,

For Universal Colorant, do you have reccommendation of maximum % water that i used to organic pigment universal colorant.

And Do you have reccomendation of type of rheology that should i used into universal colorant

Dear Nurtina, the amount of water in a universal colorant depends on, amongst others, the type of pigment + dispersant(s) and the desired rheology of the colorant. Typically, the amount of water in universal colorants that are based on organic pigments is in the range of 40-55 weight-%. The viscosity of colorants must be between certain boundaries, depending on the way the colorants are stored, transported and dosed. The viscosity must be high enough to prevent sedimentation and low enough to enable dosing of the colorants.